Ferromolybdenum

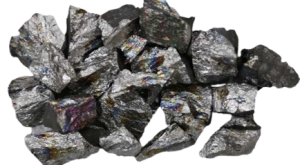

We are proud to offer the achievements of engineering and chemistry knowledge, along with our experiences in the ferroalloy industry of our beloved country, to related industries through the production of quality products. The range of products produced by this knowledge-based company in the ferroalloy industry focuses on ferromolybdenum. Ferromolybdenum is an alloy metal of iron and molybdenum which is used to enhance the hardenability and corrosion resistance of steel, superalloys, and cast iron.

Ferromolybdenum alloy, a reliable choice for the steel and metallurgical industries since ancient times. It is available in various grades, mainly produced in two types

(one for the United States and the other for the European Union) with molybdenum content between 60 and 75%.

grain refinement of the produced alloy

- 03-20mm

- 10-50mm

- 10-100mm

Color: Silver gray/gray

Melting point temperature: 1900 degrees Celsius

Packaging: Steel drums (25Kg, 50Kg, 100Kg & 250Kg) or 1-ton bags

Ferromolybdenum applications

Ferromolybdenum is used in combination with other alloying elements to produce alloys with specific physical properties, as well as stainless steel, heat-resistant steel, acid-resistant steel, and tool steel. Adding ferromolybdenum to alloyed cast irons improves the structure of cast iron parts and increases strength. In a summary of the benefits of ferromolybdenum, it can be stated that adding this alloy to the steel manufacturing process:

- Improves the properties of steel

- Causes the produced steel to have a uniform microcrystalline structure

- Reduces the eutectic decomposition temperature of steel.

- Expands the range of quenching and annealing temperatures of steel.

- Eliminates the brittleness of nickel-chromium steel and increases its strength and toughness.

- Increases the resistance of steel to grinding and impact.

- Causes the produced steel to have a uniform fine-grained structure and significantly increases the hardenability of steel.

- In steel, molybdenum can replace tungsten.

Ferromolybdenum chemical compounds

| Type | Mo (%) ≥ | Si (%) ≤ | S (%) ≤ | P (%) ≤ | C (%) ≤ | Cu (%) ≤ | Sb (%) ≤ | Sn (%) ≤ |

|---|---|---|---|---|---|---|---|---|

| FeMo 70 | 65.0 ~ 75.0 | 1.3 | 0.10 | 0.05 | 0.10 | 0.50 | — | — |

| FeMo60-A | 55.0 ~ 65.0 | 0.5 | 0.10 | 0.04 | 0.10 | 0.50 | 0.04 | 0.04 |

| FeMo60-B | 55.0 ~ 65.0 | 1.2 | 0.10 | 0.05 | 0.10 | 0.50 | 0.05 | 0.06 |

| FeMo60-C | 55.0 ~ 65.0 | 1.0 | 0.10 | 0.05 | 0.10 | 0.50 | 0.08 | 0.08 |

| FeMo60 | ≥ 60.0 | 1.0 | 0.10 | 0.05 | 0.15 | 0.50 | 0.04 | 0.04 |

| FeMo55-A | ≥ 55.0 | 1.0 | 0.10 | 0.08 | 0.10 | 0.50 | 0.05 | 0.06 |

| FeMo55-B | ≥ 55.0 | 0.9 | 0.10 | 0.09 | 0.15 | 0.50 | 0.08 | 0.08 |

It should be noted that the most important practical application of ferromolybdenum is related to its use as a ferrous alloy and depending on the amount of molybdenum content in it, is used in the production of the following tools:

- Military hardware and tools

- Various types of equipment and machinery

- Material transportation pipes in oil and gas refineries

- Charging parts and rotary drills

- Different types of automobiles including trucks

- Ships and locomotives

- Heat exchangers

- Stainless and heat-resistant steels

- Plastics and storage containers

Ferro molybdenums with high molybdenum content are widely used in the production process of high-speed machined parts, as well as screwdrivers, molds, heavy casting tools, and many types of ball and roller mills.